In this second of three posts on the traditional diamond industry, we look at what happens to Diamonds after they’ve been mined.

In the last post, we looked at what mining companies do in order to find and extract raw natural diamonds from the earth. We introduced you to the dark side of the sparkle, due to the inherent flaws in the Kimberley Process, the detrimental impact of diamond mining on the environment and its inhabitants, and the very real prospect of your treasured jewellery funding violence and war.

In this post, we follow the diamond journey to its next stage: from raw to polished gem.

The miners have hit paydirt! Now what?

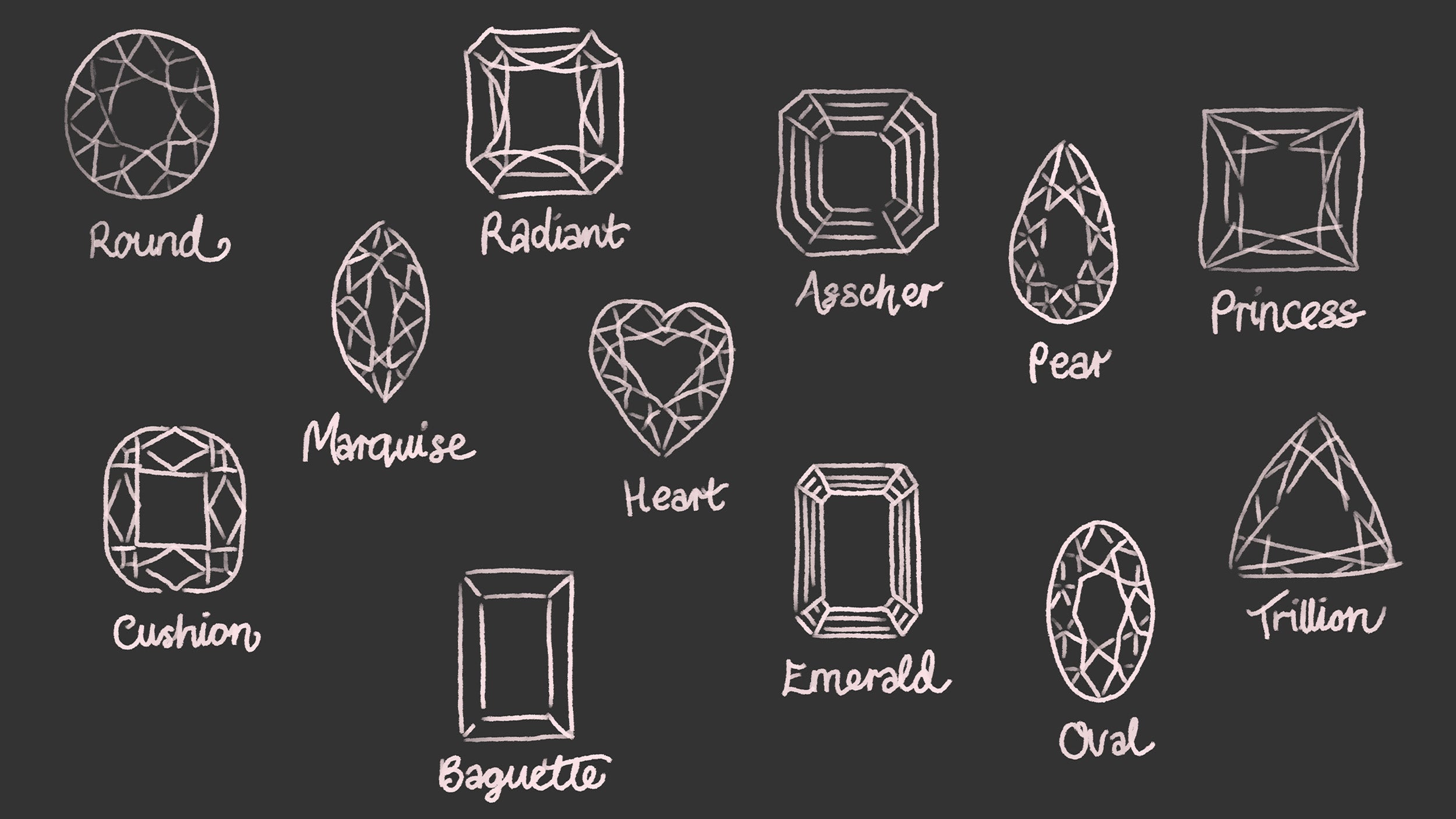

Once they are processed, raw, rough, or uncut diamonds (all different terms to mean an unfinished, unpolished stone) are evaluated for clarity, colour, carat and overall shape. ‘Gem grade’ stones are then sent off to have their most important ‘C’ taken care of: a high quality cut.

We will explore more about the Diamond C’s in our upcoming post.

At this point, we imagine an artisan, a specialist craftsman cutter sitting at a well-worn workbench, toiling away to uncover the perfectly cut diamond to be set in a piece of jewellery. Unfortunately, though not totally unfeasible, the chances of this being the case for the natural diamond you have your eye on, are extremely slight.

Who is turning a lacklustre stone to a dazzling, precious diamond?

India’s poor labour conditions allow companies to make hefty profits by exploiting unregulated workers, so it’s no coincidence that 90% of gems on the global market are cut and polished there. It’s true, not all companies operating diamond processing factories are enforcing slave labour conditions so buying from India is not a guarantee of poor conditions. However, large scale investigations have uncovered questionable practices with a lot of smaller operations, where workers live, eat and sleep onsite, including inadequate toilets and ventilation. Over 80 per cent of the workforce earn from 1 – 25 rupees per stone (AU 50c or less) for a skilled service that adds the most value to the diamond in the entire process.

The very real consequence of these operations are mass suicides of workers who feel they cannot speak up for fear of losing their jobs and can’t see another option.

That’s why at AïANA, we take our diamond sourcing as seriously as if people’s lives depend upon it. It would be much easier to create our jewellery ‘the way everyone else does it’ but we’re taking the harder road to ensure we don’t have a hand in these cruel conditions. We’re proud to be able to offer that reassurance to you, too.

Why did we mention ‘Laundering’?

The unfortunate reality is, even if the stone is legitimately Kimberley Process (KP) certified, it only applies to rough stones (topic we will discuss in our upcoming post). With diamonds changing hands often and many times prior to cutting and polishing, in the end the diamond could have come from anywhere. Until there is an enforced, unified, and most importantly functioning system all the way from mine to finished piece, you’ll never really know whether your diamond is conflict free, or has been part of funding unlawful operations.

We guarantee that every diamond set in an AïANA jewellery piece has been processed by master cutters in ethical conditions.

References: